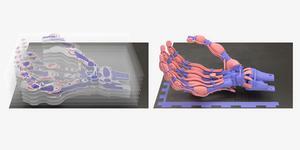

We tend to think of robots as highly engineered with huge numbers of complex and expensive parts, but this shows a different path. There may be a future class of plastic robots that are so cheap they are almost disposable.

The more AI develops, the more capable it will become in making these types of robots powerful. Furthermore, as they are 3D printed, individuals may be able to make their own. Perhaps they won’t be as powerful, or last as long, as the expensive metal ones. But if you can print your own at home to do simple tasks, this way of doing robotics could still be popular.

Here’s a video where Robert Katzschmann, the lead developer, shows this in action.

The article doesn’t mention AI at all. Where are you getting that from?

Yeah… I work in orthotics and prosthetics, and have been hearing about 3d printed limbs replacing traditional prosthetics for about a decade now.

The biggest problem is that most of these designs are made by 3d printing enthusiasts that have zero education in medicine or material sciences. They don’t know the proper therapeutic application of prosthetics, nor how materials interact with human physiology, or how giving a patient a substandard prosthetic may severely increase the chance of the pt rejecting the prosthetics in the future.

Well, if you read the article, the study authors are very well versed in material science. I’d be very surprised if there wasn’t a multidisciplinary team working on this project.

I mean the article didn’t really talk about the application, it just focused on the printing.

Just because you specialize in new types of polymers doesn’t mean you are an expert in the application of those polymers. Prosthetics require a level of durability that exceeds the limited strengths of most all plastics.

There’s a reason we fabricate with materials like carbon fiber and titanium, and even those require regular maintenance and replacements.

Westworld

Plastic people! Oh, baby, now you’re such a drag